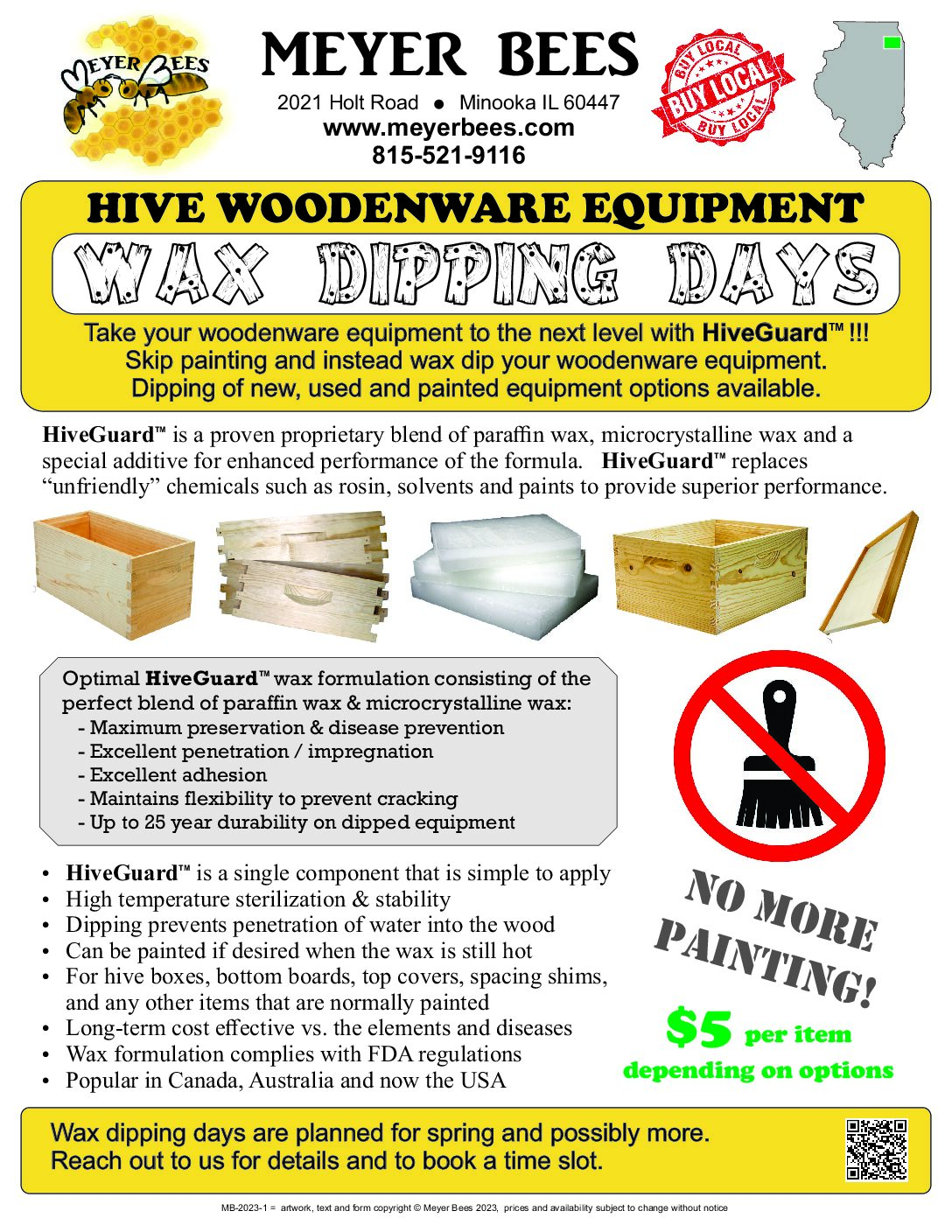

Wax Dipping Bee Boxes – paraffin & microcrystalline wax hive dipping dates are planned for early 2026. Dip beehive equipment (new or used) to preserve and protect. You can bring your own woodenware equipment to our dipping days or we have all the various sizes of bee box equipment available for purchase including 10 frame, 8 frame and 5 frame here both assembled and unassembled available for wax dipping. We also have already dipped wax beehive equipment available here that is ready to go.

If you choose to paint the wax dipped hive equipment while it is hot after dipping there will be an area set up for this process. You will need to bring your own hive paint, brushes, rollers, etc. and cleanup supplies or zip lock supplies for storing the brushes / rollers, etc.

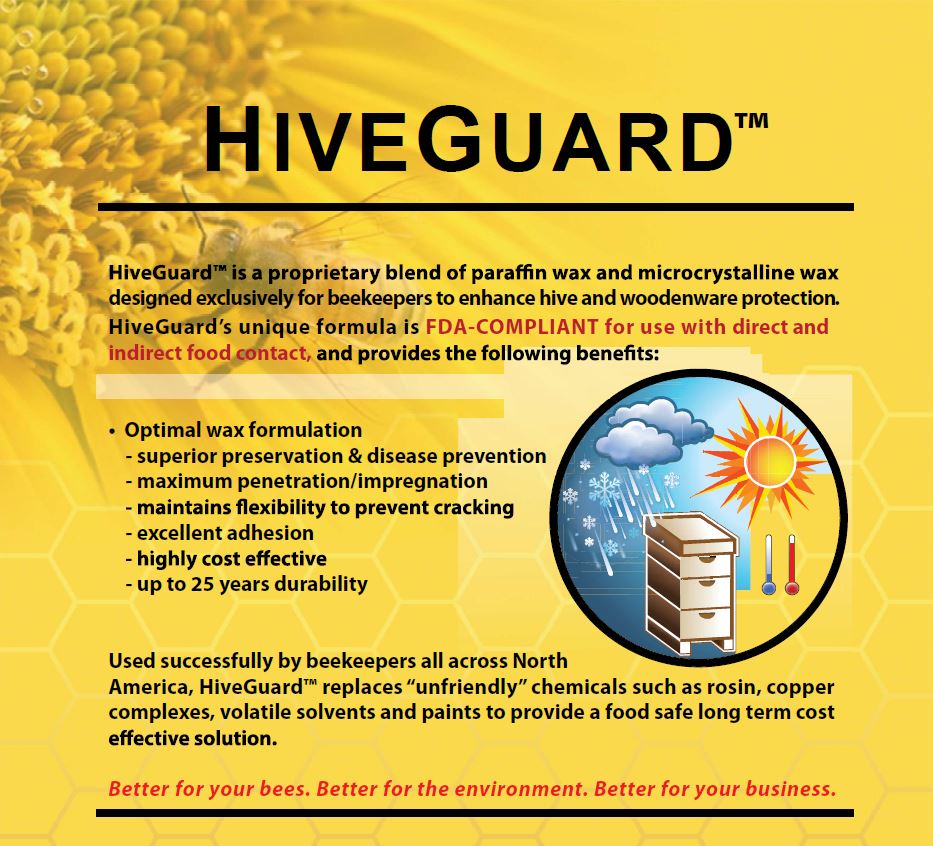

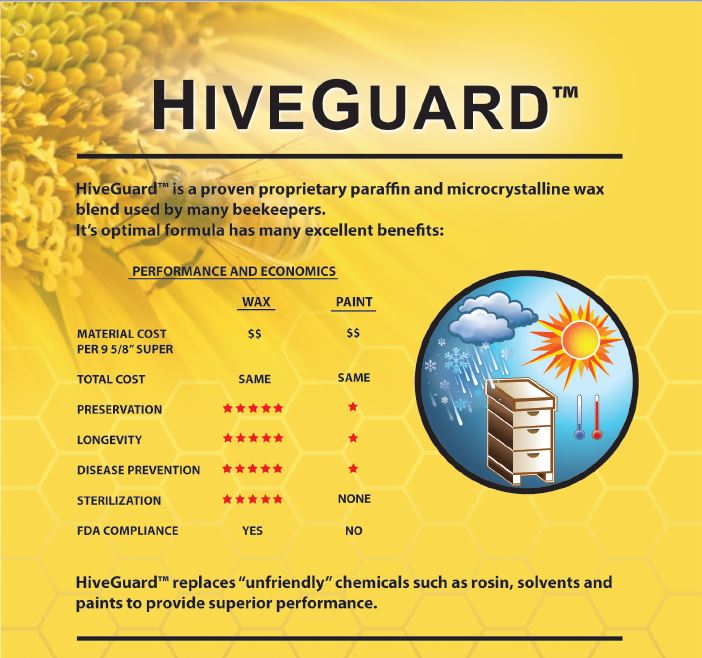

We wax dip bee boxes with HiveGuard™ which is a proven proprietary blend of waxes developed in Canada which is currently used by many beekeepers in North America, Australia, Canada and beyond. Bulk blocks of HiveGuard wax can be purchased by the box or larger quantities (pallets) at this link -> HiveGuard Wax

Dipping beehive equipment with Hive Guard™ wax has many excellent benefits:

- Optimal beehive wax formulation consisting of the perfect blend of paraffin wax, microcrystalline wax and a special additive for enhanced performance

- Maximum penetration / impregnation

- Excellent adhesion

- Maintains flexibility to prevent cracking

- Maximum hive equipment preservation and disease prevention

- Dipping prevents the penetration of water into the wood

- Up to 25 years durability

- High temperature sterilization & stability

- Can re-dip/rejuvenate woodenware years later

- HiveGuard™ wax formulation complies with FDA regulations

- Long-term cost effective vs. the elements and diseases

HiveGuard™ is a single component that is simple to apply. Can be used on all styles of wooden ware equipment like hive boxes, bottom boards, top covers, spacing shims and any other items that are normally painted. Items that include metal components like top covers and screened bottom boards may have a thin layer of wax remaining on the surface that needs to be scraped away. We are experts in dipping beehive equipment and dipping procedures.

The beehive wax dip process replaces “unfriendly” chemicals such as rosin, solvents and paints to provide superior performance.

If you reserve a spot we will email you with additional details as the “woodenware wax dipping date” gets closer. Dipping days will take place at the Minooka IL apiary.

Additional information on using wax to preserve bee hive equipment can be found at the following wax dipping links ->

Australia research project – hot wax dipping of beehive components for preservation and sterilization